Editorial by Geoff Blunt

If you’re a member of staff who works with chemicals, the chances are you’ve already been introduced to LabCup, or you will be over the next year. LabCup is an online software package aimed primarily at chemical inventory management. The University has decided to implement it across the entire institution by 2020, with no exceptions. The Faculty of Science and Engineering have already rolled it out to approximately 2/3 of Schools and Research Institutes, and the Faculty of Biology, Medicine and Health will begin this process later on this year.

If you’re a member of staff who works with chemicals, the chances are you’ve already been introduced to LabCup, or you will be over the next year. LabCup is an online software package aimed primarily at chemical inventory management. The University has decided to implement it across the entire institution by 2020, with no exceptions. The Faculty of Science and Engineering have already rolled it out to approximately 2/3 of Schools and Research Institutes, and the Faculty of Biology, Medicine and Health will begin this process later on this year.

For anyone who hasn’t already encountered it, LabCup performs a variety of functions, but at its most basic it’s a database containing information about the chemicals in your lab, where they are stored, and the safety data related to them. This is not really an innovation; many labs have stored this information in a variety of ways including written lists, Excel spreadsheets and other lab management software like Quartzy. So what makes LabCup worth the University investing in so totally?

Perhaps the biggest reason to invest in chemical inventory software is the increasing need for the University to keep track of radio-chemicals, controlled drugs, chemical weapons and their precursor materials. Every year groups are asked to check their labs for chemicals set out in the various schedules in order that these can be reported to central agencies acting on behalf of government. This exercise has been described as cumbersome and prone to errors. Following the implementation of LabCup, this should become a simple exercise of interrogating the database to obtain an automatically-generated report. The need to contact each group individually and collate numerous sporadic responses is gone. In an emergency situation, the database can be used to alert fire crews to the location of hazardous chemicals and other substances they may need to avoid, or at least be aware of, when tackling a blaze.

One of the major advantages for LabCup is that everyone will be required to use it. That doesn’t in itself sound so great, but it does mean that there will be support for it centrally, and that labs that share resources will be using the same systems. The scale of the University’s commitment to LabCup also means that the company will customise the software to increasingly integrate with our other IT systems over time, including potentially Oracle in due course. Limited information about chemicals will be visible to other people within the same Faculty, so if you get to the end of your experiment and find that the undergraduate student has used up the chemical you need, you should be able to track some down and borrow it from a neighbouring lab. Similarly, if you only need a small amount of a chemical for a “look-and-see” experiment, there should be no need to buy an entire bottle, which you may never need again; you could borrow some off another group instead.

Edinburgh University Chemistry department have reported a 25% saving in chemical purchases and disposals following the implementation of a similar system, so the incentive for cost-conscious groups to participate is clear.

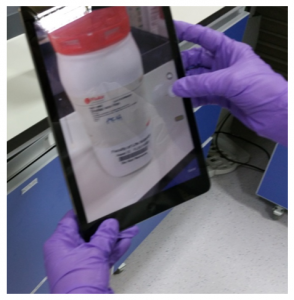

Another reason for choosing LabCup was the clever features such as image and barcode recognition, which streamline the boring data-entry process. As well as having a web interface, there are apps for Apple and soon Android devices which are mobile and can readily be taken into labs to access chemicals in situ. When you enter a chemical onto the system, you have the option of simply taking a photo of the bottle’s label; in a lot of cases, LabCup will identify the chemical name, manufacturer and product number and other critical information without you having to enter the data by hand. Furthermore, it will then search an online database and download the safety data sheet for the chemical and add it to the database automatically. There are some caveats to this: the label has to be in a good state, the bottle has to have been bought relatively recently (and from a mainstream manufacturer), but when it does work, it is a big time-saver. If you already had an inventory spreadsheet or other digital format, these can be uploaded to save you repeating work you’ve already done. As your inventory begins to grow on the database, it can also offer you helpful advice about incompatible chemicals being stored in the same location, and for some potentially dangerous chemicals it will even, for example, suggest a short expiry date to reduce the risk of crystallisation.

Another reason for choosing LabCup was the clever features such as image and barcode recognition, which streamline the boring data-entry process. As well as having a web interface, there are apps for Apple and soon Android devices which are mobile and can readily be taken into labs to access chemicals in situ. When you enter a chemical onto the system, you have the option of simply taking a photo of the bottle’s label; in a lot of cases, LabCup will identify the chemical name, manufacturer and product number and other critical information without you having to enter the data by hand. Furthermore, it will then search an online database and download the safety data sheet for the chemical and add it to the database automatically. There are some caveats to this: the label has to be in a good state, the bottle has to have been bought relatively recently (and from a mainstream manufacturer), but when it does work, it is a big time-saver. If you already had an inventory spreadsheet or other digital format, these can be uploaded to save you repeating work you’ve already done. As your inventory begins to grow on the database, it can also offer you helpful advice about incompatible chemicals being stored in the same location, and for some potentially dangerous chemicals it will even, for example, suggest a short expiry date to reduce the risk of crystallisation.

While the software involved is very clever, there’s no getting away from the fact that this is a lot of work to set up initially, and then a fair amount of maintenance is required to update the inventory as new chemicals are bought and old ones used up. Since technical staff are often called on for complex, long-duration tasks, there’s a high chance that PIs will seek to delegate this to them. So how can we manage this? Here are three approaches:

Be clear about the responsibility – these chemicals are the responsibility of the person whose money paid for them, usually the PI or line manager, and they will be accountable if mistakes are made. So if you’re asked to take this on, be specific about the amount of resources you will need (time out of your other duties, participation from other lab members, or both), and make sure these are in place before agreeing to start the process.

Don’t be the single point of failure – this system will only work if it’s kept up-to-date. If you’re the only person maintaining the database for your group, what will happen when you are away? Your PI or line manager will need to make provision for this.

Exploit the benefits of the system – fed up of being constantly asked where chemicals are? Or how to find chemical safety data for new risk assessments? Point lab members to LabCup, they should be able to search out the location of any chemical and its safety data from any computer.

It will be interesting to see, as the system becomes embedded in the University, whether LabCup use starts to crop up in job descriptions – and if it does, whether it’s primarily in the technical roles. We are often reminded, after all, that Health and Safety is everyone’s responsibility!

Yvonne Duxbury, David Dennington, Colin Greensmith and their new member of staff Sarah Warburton gave blood at the blood donation centre Plymouth grove on the 11th May. They, Stu Marshall and Sally Ashe, staff from MVU (Microbiology and Virology Unit) are booked to donate again in August.

Yvonne Duxbury, David Dennington, Colin Greensmith and their new member of staff Sarah Warburton gave blood at the blood donation centre Plymouth grove on the 11th May. They, Stu Marshall and Sally Ashe, staff from MVU (Microbiology and Virology Unit) are booked to donate again in August. Have you seen this season’s addition of Learning For All, your easy access round up of what is available from Staff Learning and Development?

Have you seen this season’s addition of Learning For All, your easy access round up of what is available from Staff Learning and Development?

The Faculty of Science and Engineering opened its doors at the Sackville Street Building so that technical staff from across the three faculties could see some of what goes on within a component of the School of Materials. This well attended Workplace Tour offered an opportunity to learn about the diverse and sophisticated industry of textiles, observing industrial scale sewing, weaving, knitting, dyeing and fabric printing equipment. These facilities are used to develop sound technical knowledge and an understanding of all the processes involved in the manufacturing of fabrics and development of fashion products. This tour looked at the facilities as well as the technical roles within the School who assist students and researchers understand the fundamental principles of materials and the manufacturing processes. Everyone enjoyed meeting with each of the technical staff as they walked us through the environment they work in.

The Faculty of Science and Engineering opened its doors at the Sackville Street Building so that technical staff from across the three faculties could see some of what goes on within a component of the School of Materials. This well attended Workplace Tour offered an opportunity to learn about the diverse and sophisticated industry of textiles, observing industrial scale sewing, weaving, knitting, dyeing and fabric printing equipment. These facilities are used to develop sound technical knowledge and an understanding of all the processes involved in the manufacturing of fabrics and development of fashion products. This tour looked at the facilities as well as the technical roles within the School who assist students and researchers understand the fundamental principles of materials and the manufacturing processes. Everyone enjoyed meeting with each of the technical staff as they walked us through the environment they work in. First stop was the Spinning Laboratory where Peter Moroz explained how they prepare/process the raw materials to produce the different types of thread, and demonstrate the various types of machinery that can be used in the process. This then lead to the Weaving Laboratory where Mark Chadwick introduced 17 commercial looms and associated preparation equipment. In this area students and researchers come to understand the craft of fabric manufacture.

First stop was the Spinning Laboratory where Peter Moroz explained how they prepare/process the raw materials to produce the different types of thread, and demonstrate the various types of machinery that can be used in the process. This then lead to the Weaving Laboratory where Mark Chadwick introduced 17 commercial looms and associated preparation equipment. In this area students and researchers come to understand the craft of fabric manufacture.