The Gatsby Charitable Foundation launched the Technicians Make It Happen (TMiH) campaign in March 2016. http://www.gatsby.org.uk/education/latest/technicians-make-it-happen-launch

It started as a gallery exhibition, which now tours around the country (particularly at education conferences) and has a campaign website http://technicians.org.uk/.

The message: The demand for technicians is growing. Their diverse skills are critical to the UK’s performance in the global business arena. Yet we face a growing skills shortfall. By training to be a technician, you could work for some of the top employers across the UK. And with opportunities available right now in an incredible range of exciting sectors including music, gaming, aerospace, film, automotive, fashion and more, there has never been a better time to become a technician. Make it happen.

There are many and varied technician stories on the TMiH website: http://technicians.org.uk/technician-stories/. It seemed that The University of Manchester would have some interesting technical stories to offer to the campaign.

Working with various individuals across all three faculties, some suitable technical roles were identified. Having willing participants, in November 2017 I submitted four “technician stories” to the campaign for consideration. The campaign organisers were so impressed with our range of technical staff they decided to come and meet with them all. In February 2018 Lauren Golding (Communications Officer, Gatsby) came along with a camera crew to meet with the technicians. This visit allowed Lauren to get a real sense of each of their stories: understanding their background, how they came to be in their technical role and why they do it. Being a very visual campaign, they were pleased to find such photogenic faces and work spaces. The technical case studies are designed to feature on the TMiH website and on social media.

The first of our case studies went live on Friday 25th May, and it looks fantastic! You can read more about Stephen Lindsay-Smith (Mortuary Technical Manager, FBMH) on the website: http://technicians.org.uk/technicians/stephen/

Throughout June and July the campaign organisers are hoping to feature the other three case studies on their website. So keep an eye out for Claire Fuzipeg (Electronics Technician, FSE), Thomas Bishop (Laboratory Technician, Humanities) and Dominika Knych (Analytical Chemistry Technician, FBMH) in the coming months.

I’m very pleased that each of the Faculties has been supportive about contributing to this campaign. It is a great demonstration of our Technician Commitment within The University of Manchester.

Author: Cassandra Hodgkinson (Technical Operations Manager, FBMH)

The Faculty of Science and Engineering opened its doors at the Sackville Street Building so that technical staff from across the three faculties could see some of what goes on within a component of the School of Materials. This well attended Workplace Tour offered an opportunity to learn about the diverse and sophisticated industry of textiles, observing industrial scale sewing, weaving, knitting, dyeing and fabric printing equipment. These facilities are used to develop sound technical knowledge and an understanding of all the processes involved in the manufacturing of fabrics and development of fashion products. This tour looked at the facilities as well as the technical roles within the School who assist students and researchers understand the fundamental principles of materials and the manufacturing processes. Everyone enjoyed meeting with each of the technical staff as they walked us through the environment they work in.

The Faculty of Science and Engineering opened its doors at the Sackville Street Building so that technical staff from across the three faculties could see some of what goes on within a component of the School of Materials. This well attended Workplace Tour offered an opportunity to learn about the diverse and sophisticated industry of textiles, observing industrial scale sewing, weaving, knitting, dyeing and fabric printing equipment. These facilities are used to develop sound technical knowledge and an understanding of all the processes involved in the manufacturing of fabrics and development of fashion products. This tour looked at the facilities as well as the technical roles within the School who assist students and researchers understand the fundamental principles of materials and the manufacturing processes. Everyone enjoyed meeting with each of the technical staff as they walked us through the environment they work in. First stop was the Spinning Laboratory where Peter Moroz explained how they prepare/process the raw materials to produce the different types of thread, and demonstrate the various types of machinery that can be used in the process. This then lead to the Weaving Laboratory where Mark Chadwick introduced 17 commercial looms and associated preparation equipment. In this area students and researchers come to understand the craft of fabric manufacture.

First stop was the Spinning Laboratory where Peter Moroz explained how they prepare/process the raw materials to produce the different types of thread, and demonstrate the various types of machinery that can be used in the process. This then lead to the Weaving Laboratory where Mark Chadwick introduced 17 commercial looms and associated preparation equipment. In this area students and researchers come to understand the craft of fabric manufacture.

A technician working in the MIB building was recently rewarded by the University’s Thank You scheme for the excellence of her record-keeping, and its impact on a patent application. Anu Balasundaram works for Professor Clare Mills’ Molecular Allergology group, preparing and analysing ‘challenge meals’ for their commercial partner, Reacta Biotech. Challenge meals are foods containing precise quantities of a known food allergen, e.g. peanut protein, or a placebo. When administered to people with food allergies in a double blind placebo-controlled food challenge under medical supervision, they can be used to give an accurate food allergy diagnosis.

A technician working in the MIB building was recently rewarded by the University’s Thank You scheme for the excellence of her record-keeping, and its impact on a patent application. Anu Balasundaram works for Professor Clare Mills’ Molecular Allergology group, preparing and analysing ‘challenge meals’ for their commercial partner, Reacta Biotech. Challenge meals are foods containing precise quantities of a known food allergen, e.g. peanut protein, or a placebo. When administered to people with food allergies in a double blind placebo-controlled food challenge under medical supervision, they can be used to give an accurate food allergy diagnosis.

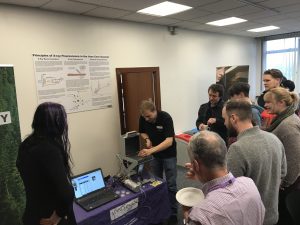

On 17th January, TEaM held one of its quarterly coffee & networking events, this time with a stall from the School of Geography, following on from feedback that these events could be improved by adding some technical focus.

On 17th January, TEaM held one of its quarterly coffee & networking events, this time with a stall from the School of Geography, following on from feedback that these events could be improved by adding some technical focus.

Director of Social Responsibility, School of Medical Science

Director of Social Responsibility, School of Medical Science