Back in June we hosted a symposium called MAKING SCALE as part of Venice Biennale Sessions. Outside of the event we were able to view the full exhibitions across the two main sites at the Giardini and the Arsenale. Reflecting on our time there the workshop staff have each picked their favourite display and summarised their thoughts on it below. If you have chance to catch it before it closes in late November let us know your thoughts! – Scott, Lara & Sarah

Scott’s pick:

Renewal: A Symbiotic Narrative – Peoples Republic of China

La Biennale di Venezia – Arsenale

I’ve been fortunate to be able to visit the Biennale several times in the last 10 years. With varied themes to explore each year across the various exhibits. I’m primarily looking out for presentation techniques and of course, anything that makes use of models to convey a message. The space occupied by the Peoples Republic of China at the Biennale’s Arsenale site has often presented a challenge for its curators in terms of its sheer scale. The display occupies one of the largest single spaces across the two main sites meaning it’s contents either have to match that in terms of the chosen artefacts or, using creative display mediums which effectively fill the space. I’ve chosen this as this year’s standout exhibit from a display point of view.

The exhibit uses a common language of materials throughout which clearly identify the contents as part of the same focus topic. Exploring the theme of laboratories and experimentation, the curators chose a range of case studies from across China that have in some way informed improved liveability in high-density built environments across the country. Quoting from the exhibition catalogue, “more than forty scroll-like columns […] generate the experience of being in a metropolis” (Xing, 2023).

Within each of these columns’ visitors can view a model of a site study that is supported by context information and imagery that steps forward through time as the density of urban areas increases.

At the far end of the rows of columns the curators placed a mirror wall which adds to the feeling of density of depth to the already huge space. The floor is also mirrored and features the year-by-year chronology of the exhibits. The columns themselves are internally lit with a frosted finish in light red and white. This theme is continued in the models themselves which always stick to this colour pallet. Materials used are primarily frosted acrylic which has been laser-cut, combined in some cases with resin 3D printed elements to match the light red/pink hues that occur throughout. Model scales vary depending on the subject site being presented.

I find this consistency in language very effective when it comes to subconsciously linking different pieces together. This is something I encourage our students to consider when producing sets of models, keeping in mind the broader style choices of their project presentation.

Overall, I feel this exhibit is neatly put together and the simple consistency of its contents help to make a huge space feel sufficiently populated with what are actually quite small exhibits.

Xing. R (May 2023) Renewal: A Symbiotic Narrative (P27), Biennale Architettura 2023 The Laboratory of the Future Participating Countries & Collateral Events, La Biennale Di Venezia

Sarah’s Pick:

Not for Sale!! – Canada

La Biennale di Venezia – National Pavilions Giardini

This was my first trip to the Venice Biennale and initially what struck me was the vast range of work on offer. Across the exhibitions there were so many varied techniques including textiles, model making and film all with the aim of getting their personal view/ message across. The scale of the event also took me by surprise as I was unaware of the vast expanse the biennial had across the city. Some highlights include, Switzerland’s pavilion ‘Neighbours’, which featured a giant carpet which explored the themes of proximity and relationships between the pavilions themselves. As well as Chinas pavilion which featured a large collection of rose prink models that showcased different ways the ever growing population could utilise space in city’s.

However, my personal favourite exhibition and the one I’ve chosen to discuss is Canadas pavilion ‘Not for sale!!’. One thing that really stuck out to me was the consistency throughout the pavilion and how they’d chosen to present the work. The site models themselves looked like a miniature version of how they had adapted the building.

Exterior of the Canada Pavilion 2023. Image Source: https://www.labiennale.org/en/architecture/2023/canada

The exhibition comments on the changing and growing gap between housing that is causing a classist urban environment, where the richest in society benefit from gaining more properties and the poorest are left in a bad living conditions with extortionate rent prices making their access to the housing ladder almost impossible. I found this angle interesting as ‘Architecture’ is the source of the problem but it can also be the solution. I took away from the exhibition the injustice that people who already have money can freely put it into more property getting richer and richer whilst doing no work, whereas people grafting daily are in a situation where a decent home feels like a luxury. An imbalance that is prevalent in much of the western world, inclusive of the UK. I felt the topic they had chosen to explore was relevant and the models used to convey the issue pushed the message by using clear visuals.

The pavilion itself had been adapted to suite the theme, being made to look like a rundown building from the outside, with boarded up panels and graffiti to represent visually some of the homes people are being forced to live in because of the housing crisis. ‘Not for sale!!’ was not only an exhibition held at the pavilions in Venice but also a live campaign to end the housing crisis. The pavilion acted as the headquarters, connecting activists and architects in one space, all with the aim to improve housing accessibility. The inside of the pavilion reflected this giving the impression of somewhere a revolution could be started. The space felt like a cabin, almost as though you were outside on the side of a protest. The models were simple, but brightly coloured so you could identify different areas and featured giant speech bubbles gave them an almost ‘pop-art’ Andy Warhol feel.

Inside the Canada Pavilion. Image source: https://worldarchitecture.org/architecture-news/fzecp/canada-pavilion-explores-tangible-forms-of-housing-crisis-at-venice-architecture-biennale.html

Many of the visuals including the models, posters and leaflets had recognisable visual such as a ‘Raised fist’ synonyms for the Black Power Movement, re-designed into a more modern style. Overall, the themes throughout the pavilion effectively strongly showcased the messages of ‘change now’ and ‘action needed’. The models were made from card and paper which to me reinforced the idea of limited resources and looked as though they had been made with solely hand-crafted techniques. This style of making is something I will encourage students to take forward within their own work as it is showcased clearly that simple techniques and shapes can create great results. The neon colours gave all the models a strong visual language that was carried through the space. I really enjoyed the incorporation of words and questions within the site models and the interpretation that models are not just a representation of something that is proposed and will happen, but instead they can be something used to inspire a better future. They featured questions about how we could readapt and make spaces around us more accessible, making you reflect on how we use and create places for example, ‘What if we, were outdoors more? With safe spaces for children?’

Overall, the movement & exhibition was positive, bringing together people to push social mobility within housing. The models used represented the change that people part of the agenda wanted to see and the whole space was utilised well.

Lara’s Pick:

‘Emotional Heritage’ – Flores & Prats Architects

As part of ‘Dangerous Liasons’ for ‘The Laboratory of the future’ curated by Lesley Lokko

La Biennale di Venezia – Le Corderie dell’Arsenale

I was fortunate enough to visit the Biennale for the first time this year. The Venice Biennale is an international cultural exhibition hosted by the Biennale Foundation in Venice, Italy. There were many exhibits in various locations around Venice to see and explore, all linked to themes around architecture. I was particularly interested in seeing how models were used internationally by architectural practices and how these were displayed. I found the site at le Corderie dell’Arsenale particularly interesting with its selection of architectural practices and design studios in ‘Dangerous Liasons.’ An exhibit that stood out to me most in the collection was Flores & Prats Architects ‘Emotional Heritage.’

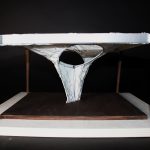

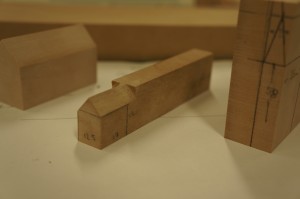

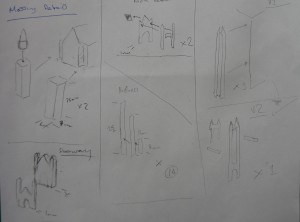

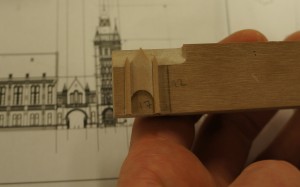

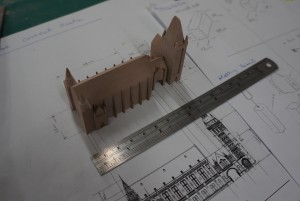

As soon as you walk into the exhibition, you are met with a busy room full of drawings, photos, films and models of varying details, scales, and purposes. On the tables and installations around the room they introduce six of the projects that the practice has been involved in. All of these projects showcase an ‘Emotional Heritage’ approach of the practice through interventions into existing buildings and the memories held inside.

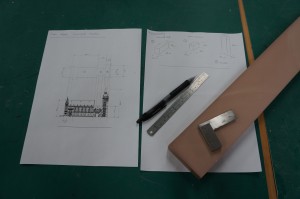

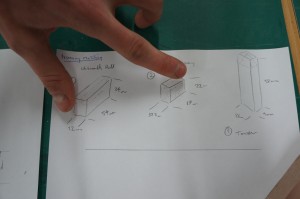

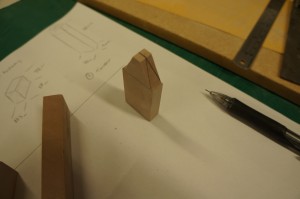

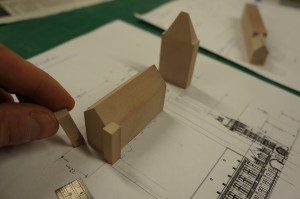

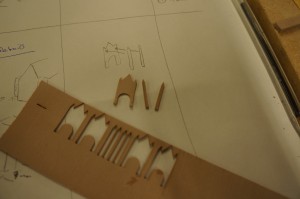

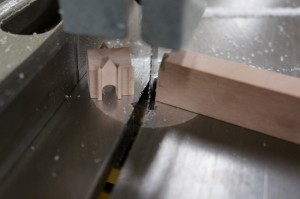

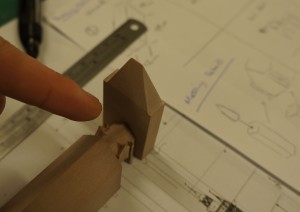

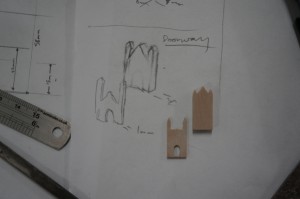

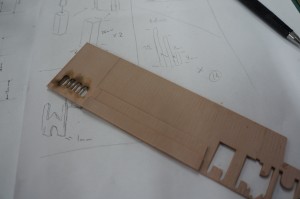

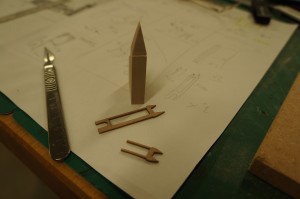

Parts of the exhibit are presented as if the project is a work in progress, allowing visitors to experience the inner workings of the design process leading up to a finished product. This fits very well within the curator’s overall themes of laboratories, imagination, and experimentation. The themes run throughout the exhibit, creating an atmosphere as if you were inside their Barcelona studio. They demonstrate a variety of model types including presentation, sectional and sketch models displayed on stands and in bespoke display containers. They also showcase animations of using models in an interactive way to explore the narratives that shape their final products.

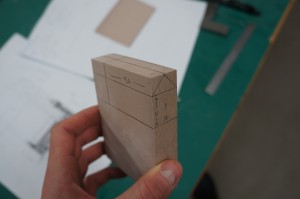

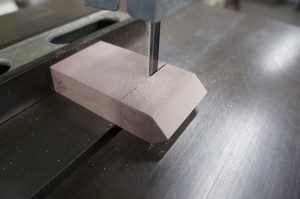

The exhibit demonstrates a variety of materials and processes, although predominantly they have chosen to use handmade processes to explore design ideas. It is interesting because the use of digital fabrication machines is often the first thought of students wanting to make models, but here is a demonstration of a practice showing that this is not a necessity. I often encourage students to consider both digital and manual fabrication methods depending on what they are trying to communicate whilst considering material, cost, and time. This is an architectural practice that uses modelmaking throughout the design process and showcasing this opens it up for discussion.

A particular favourite model of mine in this exhibit is the model of the exhibit itself. I love all the small, intricate details and how it was used as a tool to help inform the design of space for the exhibit. Even after the exhibit is erected, it still offers value through the capture of a moment in time which very much relates to the practices approach of memories within a building for ‘Emotional Heritage.’

Overall, I feel this exhibit offers a great insight into how Flores & Prats Architects use models, drawing and film to create discussion between visitors, clients and builders of their architectural designs. They very much use model making as a tool throughout the design process to explore and develop ideas before coming up with the final design.