During December 2019 I visited la Facultad de Arquitectura y Urbanismo (the Faculty of Architecture and Urbanism) part of Universidad Central del Ecuador, in the country’s capital, Quito. At 2980m altitude, the beautifully designed brutalist building of the faculty felt like a hidden gem among the other buildings from the university campus, the semi-circular repetitive roof structures transmitted an equilibrium very fitting for a place dedicate to design and architectural education.

While talking to a first year architecture student I understood that in the early stages a big emphasis is put on developing hand drawing skills and the designs are tested through simple hand crafted models. I was impressed of the amount of models the students were producing, and how they were finding enough time to invest in this as the course content was broader than what I had experienced during my Part 1 in the UK.

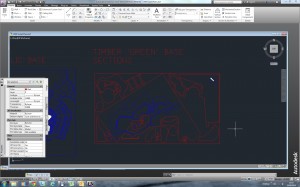

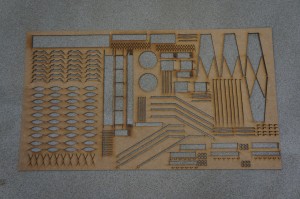

The main reasons for this were the materials and methods being used. After observing only a few models I noticed that balsa wood is everyone’s favourite material. This soft fibre wood allowed the students to quickly craft sketch models, quick prototypes and many times it was used even for the final presentation models. The ease with which this material can be manipulated allowed the students to recreate the workshop environment in their homes and with only a scalpel and some glue they were constructing a wide variety of models. Sometimes for the final exhibition models the faculty’s laser cutter was used for achieving more precise cuts on fine details.

It’s no accident that balsa is used so extensively as it is a locally grown material which is widely available at a very low price (I noted it was approximately 10% of the price at which we purchase balsa in the UK). Balsa is a native species to Ecuador and the country is the world’s leader in balsa production, with over 90% of the wood being exported all over the world. Because of the county’s altitude, climate and environment, the balsa from the Ecuadorian forests is privileged as it offers a more stable wood in terms of density. Balsa is not an endangered species due to its fast growth and facility of reproduction.

(Information about balsa production: www.euronewsa.com/balsa.html)

This made me reflect upon how we sourced materials during the projects which I undertook at MSA. Few projects asked us to consider the usage of local materials, and when we do consider it, this is mostly seen as a constraint. However, not very often do the students question from their own initiative the provenience of the materials which they use, especially in a world where everything is available at a few clicks away. From my observations gathered whilst visiting the architecture school in Quito, I noticed that the use of local materials is widening the possibilities in terms of modelmaking and construction. By using these materials so often the students developed skills which allowed them to create a wide variety of models by understanding the different properties of the wood.

While visiting an exhibition with projects from the masters of architecture course I noticed several models which used plaster or plywood, therefore being more developed in terms of material complexity, but the combination with the balsa wood was omnipresent. In the project from the below images, the student used a series of volumetric plaster models which were combined with red painted key elements of the design. The red colour was then used in the sectional model of the final design and within the architectural drawings as a highlighting method.

Apart from testing design concepts through models I noticed the importance of the technical side within their architecture degree. An application through modelmaking was the project visible in the images from below, where groups of students tested different types of joints which could be used in creating a geometrical sphere. Several methods of joining the wooden pieces were tested, including connections that used sections of recycled plastic pipes or tubes, as well as using bespoke metal fixings which were screwed into the wood. Regardless of the complexity, these constructions were built with only using basic tools and local materials.

Being exposed to the modelmaking culture of the architecture school in Quito was a good lesson about the importance of valuing local practices and materials and making the most of what resources you have to hand. Perhaps the ease with which we can access materials produced all over the world here in the UK makes us, unintentionally, a bit ignorant of the energy and effort it takes to produce them. As a result the profession is quite wasteful. It would be an interesting project set out to find the local equivalent of the balsa wood source in Ecuador right here and incorporate it into our models. This would be both convenient and more sustainable, helping to reduce our carbon footprint as we progress through architecture school.

This article was written by Patricia Belcin, Teaching Assistant at B.15 Modelmaking workshop 2019/20.