One of the most important habits we can pick up as designers and makers is to make the most efficient use of anything that is freely available to us. It is essential that we consider the conservation of materials and the reduction of waste from our projects in order to play our part in maintaining a broader sustainability for the future. The least we can do is to efficiently plan how best to use the material we are working with.

This can be seen as a hindrance to quickly starting a project but in reality, effective planning can help reveal more appropriate materials for a particular task as well as best use of those at hand. This saves money and expands our understanding of material qualities.

Before planning based on an infinite amount of material it’s good practice to break down your projects into components as a list or drawing which can be referred to when assigning materials. With this reference at hand we can decide on the most appropriate materials for each component or group of components.

An example of this might be all ‘green’ or natural areas of a site could be represented using timber against a coloured acrylic as the man made roadways. Knowing this we could separate those components and begin collecting materials that suit the required sizes.

Looking through off-cuts left from past projects it is likely you can produce much, if not all of your model for free by using these.

Using Sheet Material for Component Layouts

By working out what you need from a particular piece of material before you begin to cut you can get the most from each piece you use – off cut or new.

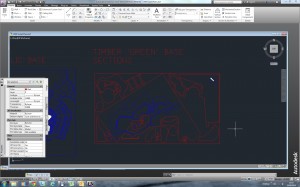

This applies to both hand drawn and CAD drawn components. Rather than placing components scattered around a sheet, tessellate and arrange them in a manner that gets the most out of each piece (See Screen Shot above for a good example).

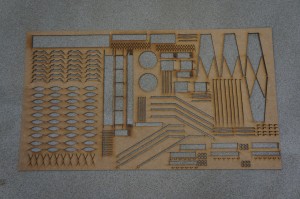

This example from Abhi Chauhan’s project below demonstrates how a piece of laser cut MDF with effective component arrangement can get the most out of a sheet of material.

Re-Use of materials and model components

Before you decide to use new materials you can also look at the role of your existing works and rework them into new ideas as demonstrated in this student video made by Signe Perkone and Sigita Zigure who graduated BA Architecture last year. Whilst we are keen to record all work produced it is impossible for us to keep everything so by re-using models this way we are helping to do our bit to reduce waste.

Scott