Laser cutters 1 and 2 (Universal Lasers)

B.15 Laser Cutting Guide

We do not take bookings for laser cutting over the phone or via email. Staff must check your file in person to advise on any changes and the time it will take before a slot will be allocated on the day you’re in the workshop.

We work using AutoCAD and prefer drawings to be correctly scaled to your model working scale and saved as .DWG or .DXF format.

Maximum cutting extents are 800mmx450mm. Always check material stocks with us before planning your drawings.

Scale factors for CAD software

1:1 – No Change

1:2 – 0.5

1:5 – 0.20

1:10 – 0.1

1:20 – 0.05

1:25 – 0.04

1:50 – 0.02

1:75 – 0.013333

1:100 – 0.01

1:125 – 0.008

1:200 – 0.005

1:250 – 0.004

1:500 – 0.002

1:1000 – 0.001

1:1250 – 0.0008

1:2000 – 0.0005

1:2500 – 0.0004

Applications for Laser 1 & 2

Deep engraving – Non-contact engraving & cutting – Drilling – Precision scribing – Mask production – Prototyping – Sign making – Architectural model making – Component marking – Film/overlay cutting – Textile cutting – Gasket cutting – production – Rubber stamps & seals – Membrane switches -plastics up to-12mm and MDF/Plywood cutting up to 6mm.

CorelDraw files and illustrator file formats can also be used.

Bed Size 800mm x 450mm

Materials that are not permitted or cannot be cut using the laser cutter at B.15

Packing cardboard (usually brown with internal corrugation – Fire risk

Metal – Engraving on the surface only.

Foam core board – Fire risk

Cricut Plotter Cutter

The Circuit can be used to create flat, cut shapes primarily from paper and vinyl. This machine is particularly useful for net shapes that can then be folded along score lines and assembled without scorching that can occur when laser cutting.

How to Prepare your Drawing File

Preparation instructions to follow. Please speak to a member of staff for information if you wish to use this machine in the meantime.

3D Printers

Our 3D Printers

- Stratasys F370 FDM Printer (Multiple single colour and Material options). Build Area: 355mm x 254mm x 355mm High

- Ultimaker S7 (Primarily PLA only) Build Area: 330mm x 240mm x 300mm

- 3DSystems Projet 360 Powder Printer. Build Area: 203mm x 254mm x 203mm High

- Stratasys Objet 30Pro Resin Printer. Build Area 200mm x 300mm x 150mm High

Cost is calculated using completed 3D Model File in the workshop. There are no ‘overhead’ costs to any type of 3D printing at B.15. Your jobs are charged at cost of the materials alone at the price they are sold to us by the manufacturer.

We will thoroughly check your proposals before approving the use of any of the machines so please allow time for this by getting in touch with us at the earliest convenience.

The machines work preferably .STL file format.

To save the file as an.STL from your chosen modelling software you must export it and if given the option save as Binary.

Your model must be a solid object not a collection of surfaces.

After you scale the model we recommend as a general rule that you check that objects component parts are not smaller than 1.5mm thick, anything smaller will be fragile and potentially not print properly.

Modelling Software

We recommend using Rhinoceros 3D (Rhino) or Autodesk 3D Studio Max. Sketchup is a good starter programme for visualisations but can often throw up odd problems when being translated for 3D printing so we advise trying to pick up the more advanced programmes such as Rhino and 3DSmax once you feel confident with your modelling.

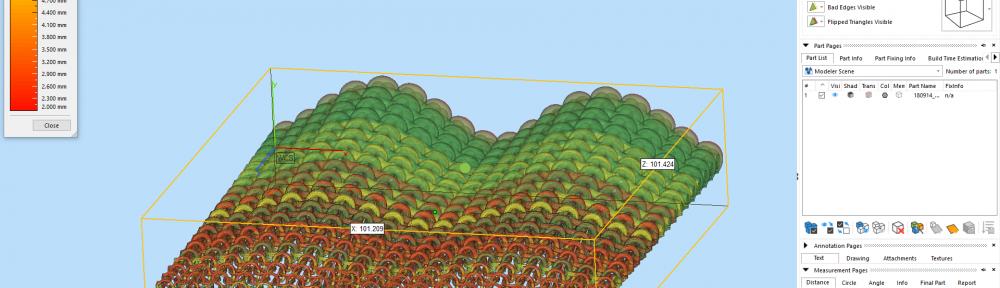

Checking your files

Once you have discussed your model with staff and completed digital modelling we can further assess and repair your files using Magics Software in the workshop.

ISEL M40 CNC Router

Operation time can vary depending on the complexity and type of CAD file used. Please consult us with your ideas before going too far into the process of modelling for this method of manufacture.

There is no time charge for using our CNC. Material is charged based on type and quantity. Speak to a member of staff for your particular project requirements.

Other Equipment

Vac forming machine

Bed size of 400mm x 210mm